pVT analysis of materials using the GNOMIX pVT apparatus

The pVT apparatus measures changes in the specific volume (Vsp) of liquids or solids as a function of pressure (p) and temperature (T) and is thus suitable for determining phase state equations. Furthermore, the apparatus enables the analysis of phase transitions (melting and crystallisation, glass transitions, isotropisation) and chemical changes. Thus, it is also useful for tracking polymerisation kinetics, degradation reactions, cross-linking, transesterification and other phenomena associated with a change in specific volume. The specific volume of the starting material must be known for defined PT conditions in order to determine the PVT parameters in absolute values. The apparatus only records the changes in specific volume (ΔVsp), not the absolute specific volume (Vsp), of the materials. Alternative for determing the changes in specific volume of materials as a function of pressure, temperature and time the pressure change can also be determined as a function of time when the specific volume and the temperature change.

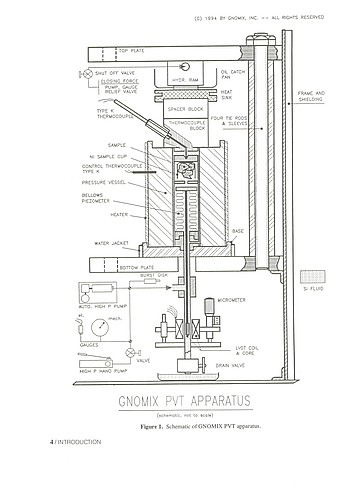

Measuring principle

The measuring principle of the method is based on the confining fluid technique. In this technique, the material under investigation (approx. 1.5 -2 ml) is surrounded by a confining fluid (usually mercury), whereby hydrodynamic pressure is applied to the sample on all sides. To ensure hydrostatic conditions, the sample may be enclosed in a small cup formed of thin nickel foil, which prevents the sample from sticking to the wall of the measuring cell. The total volume of the measuring cell is about 7 ml.

The apparatus can determine data in the pressure range from 10 to 200 MPa (in steps of 10 MPa) and temperature range from room temperature to 400 °C. For isothermal standard runs (ITS), at a defined temperature, the pressure increases from 10 MPa to 200 MPa and ΔVsp is recorded in steps of 10 MPa. The volume value at ambient pressure (0.1 MPa) is automatically extrapolated from the volume values between 30 to 10 MPa (in 1 MPa steps) using the empirical Tait equation from the GNOMIX software. After each run, the next temperature is addressed and a new isotherm is measured.

Isobaric (IBA) heating and cooling runs can be performed at any pressure between 10 and 200 MPa with heating rates up to 15 K/min. The cooling rate is limited by heat exchange and is less than 2 K/min below 100 °C and decreases further with decreasing temperature. In a special data acquisition mode (DAQ), it is possible to follow changes in specific volume at constant pressure and temperature that may be caused by chemical changes or phase transitions. While the accuracy limit for absolute values of the specific volume is within 0.002 cm3/g (above 200°C at < 0.004 cm3/g), volume changes down to 0.0002 cm3/g can be resolved with confidence.

The shape and phase state (solid, viscous or liquid) of the samples to be analysed are variable. Solid samples with inaccessible pores are not suitable, nor are materials that can react with stainless steel or the surrounding liquid. Fine powders and easily evaporating samples cannot be measured either, as the cell must be evacuated to 0.0002 Tor during the filling process.

Details of the apparatus can be found in:

- P. Zoller, D. Walsh, Standard Pressure –Volume –Temperature Data for Polymers, Technomic, Lancaster, PA 1995

- Y.A. Fakhreddin, P. Zoller, Society of Plastic Engineers ANTEC’91, 1991, 36, 1642.

- J. He, P. Zoller, J. Polym. Sci.: Part B: Phys. Ed. 1994, 32, 1049.

- J. He, Y.A. Fakhreddin, P. Zoller, J. Appl. Polym. Sci. 1992, 45, 745.