Joint project: Development of new techological solutions for the tailored preparation of nonwovens for oil filtration basing on analytical, textile-technological and application-related investigations

Sponsors

Federal Ministry for Economic Affairs and Energy via AiF within the Industrial Collective Research (IGF) program

Förderkennzeichen 17515 BR/1

- Forschungskuratorium Textil e.V.

- Forschungsvereinigung Antriebstechnik e.V.

- Forschungs-Gesellschaft Verfahrens-Technik e.V.

- Gesellschaft für Chemische Technik und Biotechnologie e.V. (DECHEMA)

Funded project partners

- Sächsisches Textilforschungsinstitut e. V., Chemnitz (STFI)

- Brandenburgische Technische Universität Cottbus-Senftenberg, Lehrstuhl Mechanische Verfahrenstechnik (BTU)

- Leibniz-Institut für Polymerforschung Dresden e. V. (IPF)

Contact persons

Dr. Karina Grundke

Dr. Astrid Drechsler

Oliver Kobsch

Associated project partners

ARGO-HYTOS GmbH, Bayer Technology Services GmbH, Bosch Rexroth Filtration Systems GmbH, Castrol Lubricants Technology Centre, flucon fluid control GmbH, Freudenberg Filtration Technologies SE & Co. KG, FUCHS EUROPE Schmierstoffe GmbH, Gebr. Röders AG, HYDAC Filtertechnik GmbH, ib24 - Ingenieurbüro Hubert Gregorius, IREMA-Filter GmbH, Johns Manville Europe GmbH, Klüber Lubrication München KG, MAHLE Industriefiltration GmbH, MANN+HUMMEL GmbH, PILL Nassvliestechnik GmbH, ROYALIN GmbH, Schaeffler Technologies AG & Co.KG, Siemens AG, SPÖRL KG Präzisionsdrahtweberei, TOTAL Deutschland GmbH, Hollingsworth & Vose, TENOWO GmbH, Norafin Industries (Germany) GmbH, REpower Systems SE, ESSO Deutschland GmbH

Duration

2012 - 2015

Abstract

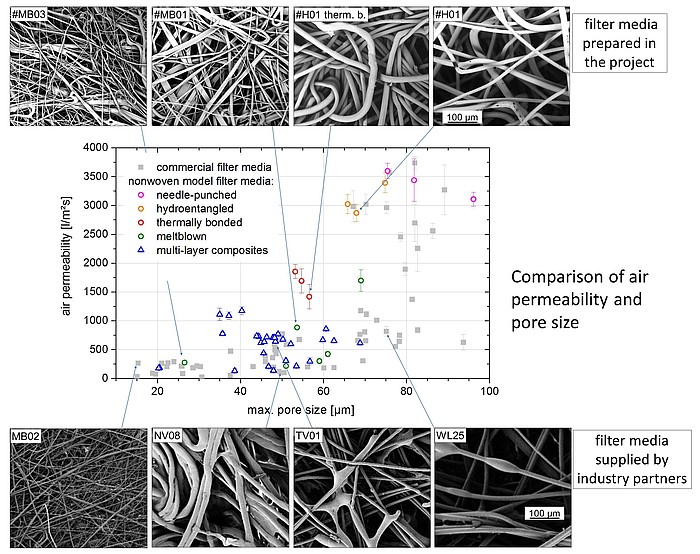

Goal of the project co-ordinated by Sächsisches Textilforschungsinstitut Chemnitz (STFI) was the basic investigation of the filtration process of gear oils as basis for the development of new filter media. The first main topic was the textile-physical, chemical, and optical characterization of commercial oil filter media and the investigation of their oil and hydrolysis resistance. Main task of the IPF group was the physico-chemical characterization of filter media using SEM, zeta potential, wetting, penetration and porosity measurements. Basing on the gained theoretical and practical knowledge, a technological basis was be created for the tailored preparation of new synthetic filter media using synthetic nonwovens. A variety of such filter media was manufactured, optimized, and extensivly characterized. The filter performance of commercial and newly developed filter media as well as other effects affecting the filtration (e.g. electrostatic charging) were investigated in filtration tests by BTU Cottbus.

The final report (in German) can be loaned from Sächsisches Textilforschungsinstitut e.V. (STFI) .

and newly developed filter media / SEM images of selected media.

Acknowledgement

The IGF project 17515 BR/1 by Forschungsvereinigung Forschungskuratorium Textil e.V. was funded by the Federal Ministry for Economic Affairs and Energy via AiF within the Industrial Collective Research (IGF) program. Furthermore the investigators thank Forschungsvereinigung Antriebstechnik e.V., Forschungs-Gesellschaft Verfahrens-Technik e.V., Gesellschaft für Chemische Technik und Biotechnologie e.V., and all other partners for funding and supporting this project.