Device and System Integration

Bioelectronic systems are typically composed of sensors and actuators linked to power, communication and computation circuits. They can be as simple as a pair of electrodes linked to a recording system, or may require more complex solid state devices and control electronics. Transducers for chemical signals, mechanical pressure, stretch, light or temperature are also common. Individual sensors and actuators are often combined in arrays. Depending on applications arrays can support several to several thousand of sensors and actuators and may have overall dimensions from the centimetre scale to the micrometre scale. Systems may be enabled for information exchange in multiple modalities including biochemical, electrical, mechanical and thermal domains and may support wireless communications and autonomy.

We aim to address challenges in processing multiple bioelectronic materials with disparate physical properties into devices, arrays and systems. The materials are often soft and hydrated which makes processing with standard microfabrication technologies challenging.

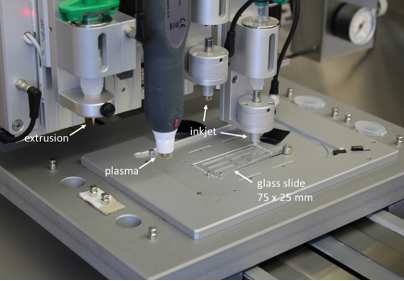

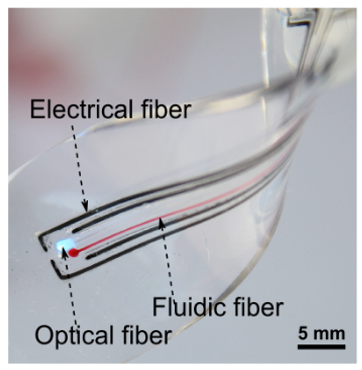

One of our key research efforts is on adapting or inventing rapid prototyping approaches drawing on various printing and 3D printing technologies (extrusion, ink-jet and electrochemical printing). This enables different bioelectronic materials to be processed together into designs tailored to applications as implants, wearables or cell culture platforms. The miniaturisation level is on the sub-mm scale.

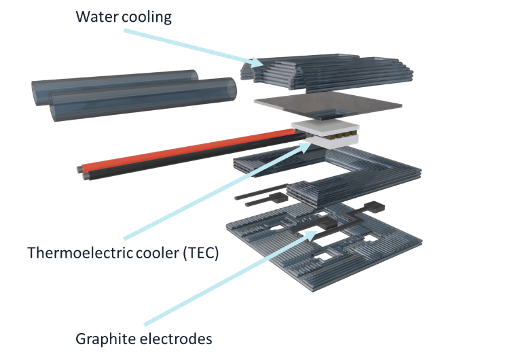

Another aspect of our effort concentrates on system integration. Arrays of sensors and actuators are equipped with custom connectors and integrated with signal acquisition and control electronics to build stand-alone systems for deployment in biological applications.

Adapted from: Athanasiadis et al, npj Flexible Electronics, 2020

Key publication: D. Afanasenkau “Rapid prototyping of soft bioelectronic implants for use as neuromuscular interfaces”. Nature Biomedical Engineering, 2020