EFRE - R&D Joint Project

Saxy Plastics - Development of bio-based and fully recyclable plastics from regional waste resources

Plastic waste pollutes the oceans, soils, and atmosphere worldwide and represents one of the greatest environmental challenges of our time. Conventional recycling processes result in a loss of material quality, making a truly circular economy unachievable to date. So-called bioplastics have also failed to gain widespread acceptance due to higher production costs and limited performance. What is needed, therefore, are newly developed materials that are both robust and versatile, while also remaining within closed-loop systems - offering real added value for both the environment and society.

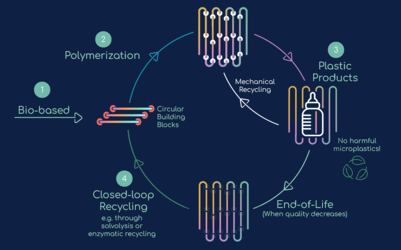

Figure 1: Aevoloop's Closed-Loop Recycling Concept (right) and the resulting various processing prototypes made of Aevoloops

*Häußler, M., Eck, M., Rothauer, D., Mecking, S. Closed-loop recycling of polyethylene-like materials. Nature 590, 423–427 (2021).

As the lead partner of the joint project, Aevoloop GmbH is developing novel plastics that are fully recyclable, bio-based, and even biodegradable. The young company from Leipzig builds on the award-winning and widely published research of Dr. Manuel Häußler. The further development of these plastics and the scaling of production capacities are at the heart of the SAXY PLASTICS project.

The Leibniz Institute of Polymer Research Dresden (IPF) is one of the project partners involved in developing application-specific compounds based on Aevoloop polymers. These customized material systems are suitable for use in packaging, technical components, and other applications. The IPF focuses on key practical aspects of polymer processing -including compounding, injection molding, polymer fiber spinning, 3D printing, and film extrusion, thereby serving as an important link between fundamental materials science and the practical development of functional Aevoloop compounds.

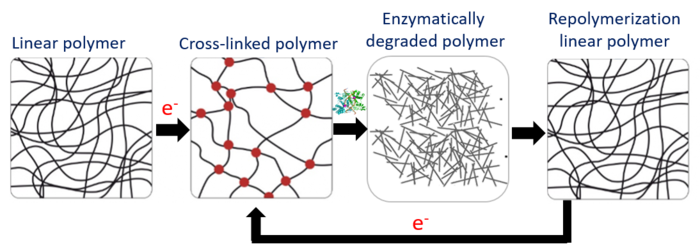

Another research focus lies in the crosslinking of Aevoloop polymers using electron beams. Since crosslinked plastics are typically difficult to recycle, the University of Leipzig is investigating enzymatic degradation as a promising solution. The goal is to significantly improve the recyclability of these materials through innovative recycling strategies.

The University of Leipzig contributes its expertise in enzymatic plastic recycling by developing enzymes capable of breaking down Aevoloop polymers into their original building blocks - even under mild conditions. This biological recycling approach conserves valuable resources and could fundamentally transform the recycling industry.

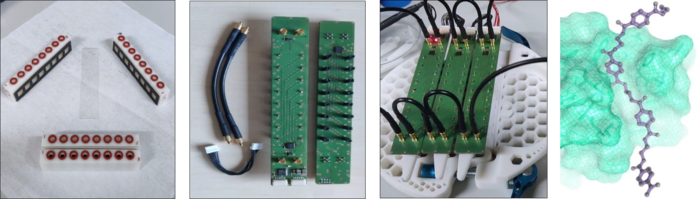

Figure 3: Experimental setup for impedance spectroscopy for the analysis of enzymatically catalyzed plastic degradation.

Right: Polyester plastic is recognized by a polyester hydrolase and then cleaved by hydrolysis.

The Center for the Transformation of Chemistry (CTC) focuses on process and materials development at both laboratory and pilot-plant scale, aiming to accelerate the transfer of innovations to industrial-scale production. Through collaboration with additional associated partners, the consortium covers the entire value chain, from raw material production and product design to recycling processes. For the Saxony region, this project marks an important step toward building a future-oriented chemical industry. By closely integrating research and application, it fosters an innovation ecosystem that helps retain skilled workers, creates new jobs, and attracts investment in sustainable technologies. Moreover, the joint efforts of companies and research institutions strengthen Saxony´s profile as an attractive hub for green chemistry and circular value creation. In doing so, the project makes a substantial contribution to the long-term competitiveness of the Free State and delivers key impulses for a forward-looking, responsible industrial policy.