Compounding & Shaping Processes

Compounding

Process controlling

Process controlling

Screw pull-out – Experiment

Compounding;

Buss-Co-Kneader;

Powder coating compounding

Compounding; Buss-Co-Kneader

Shaping

Horizontal and vertical machine positions possible

Experiments vs. Simulation; process & morphology

Experiments vs. Simulation; process & morphology

Blown film extrusion

Characterization

Cold interface, crystalline morphology, polyamide-polyamide, polarized light microscopy

Skin morphology, polylactide, polarized light microscopy

Flow induced crystalline morphology, polyethylene, polarized light microscopy

Info flyers

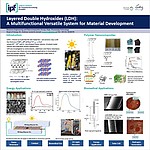

Poster

A multifunctional versatile system for material development

Useful links

Contact