Detection of liquids and gases via electrical resistance measurement

In the NB department experiments on the detection of liquids (such as various solvents or water) and gases (e.g. saturated or diluted solvent vapors or atmospheric humidity) are carried out on electrically conductive polymer composites with carbon-containing fillers. For this purpose a measuring station was set up that allows a polymer composite sample to be exposed to the liquid or gas and the electrical resistance of the sample to be measured simultaneously. The interactions of the liquid and gas molecules with the sample can lead to swelling of the polymer and thus to expansion of the conductive filler network, which results in an increase in electrical resistance. The strength of the interaction of the polymer with liquids or gases can be estimated by calculating the Flory-Huggins interaction parameter. The expansion of the filler network is determined by both the swellability of the polymer and the initial density of the electrically conductive network. For a spontaneous increase in resistance, a rapid separation of filler contacts is necessary. This is most likely to be ensured by a loose network, i.e. when using polymer composites with filler contents just above the electrical percolation concentration.

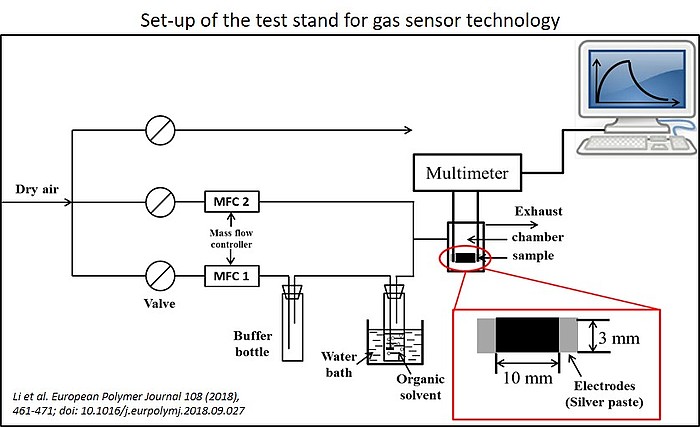

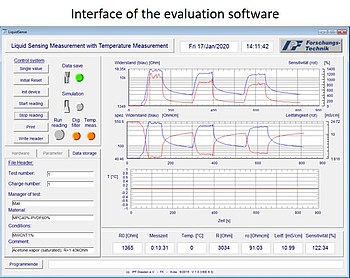

The measurement of the initial electrical resistance of the polymer composite R0 is first carried out in air. Then the sample is flushed evenly with the liquid or gas and the resistance (R) is measured as a function of time. The relative resistance change Rrel is a measure of the sensor response of the material and is calculated as follows: Rrel [%] = (R-R0)/R0⋅100%.

In cyclic experiments, where the sample is exposed to the liquid or gas and air several times in alternation and for a limited time, the reversibility of the sensor response can be determined. For gases, the measurements can be carried out either in a saturated gas atmosphere or at defined gas concentrations, which can be adjusted via a controlled mixture with air.

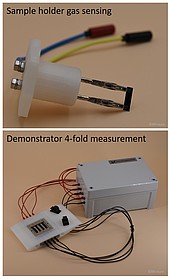

For liquid sensing, U- and rod shaped samples are used where the legs are electrically contacted and only the lower part is immersed in the liquid. For gas sensing, rectangular samples are predominantly used. In principle, fibres or fibre bundles can also be measured. The samples are contacted by coating the contact points with conductive silver and fixing them between two crocodile clamps. The electrical resistance is measured using a Keithley Sourcemeter 2400 and is recorded and evaluated using a software developed at the IPF (Research Technology Division). From the measured electrical resistance values and entered geometry values, the specific resistance and the conductivity and from these the resistance changes are calculated as a function of time and displayed graphically. The data and corresponding diagrams are stored in an Excel file.

Technical data

- Design of the measuring stands: In-house development IPF

- Measuring range: Gases at room temperature, liquids also at higher temperatures due to temperature control in the thermostat.

- Electrometer: Keithley Sourcemeter 2400, measuring limit approx. 200 MOhm

- Software: In-house development of the research technology department based on an Agilent VEE application. Recording of the measured values including calculations (specific values, relative values) and presentation in an Excel file.