Department Materials Engineering

Fields of work

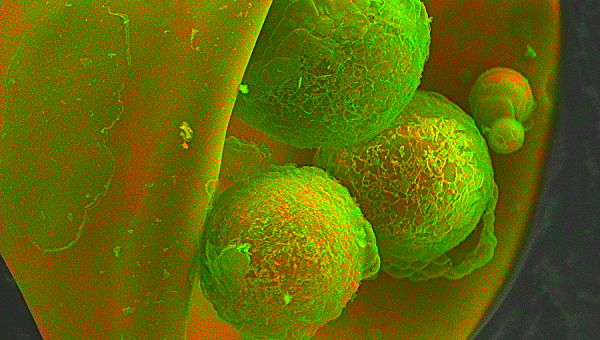

The interdisciplinary approach is focussed on the development of tailored polymer materials in relation to their application as well as to their sustainability. The main working field is to discover the structure-property-relations including the chemical and physical built up, as well as the phase morphology.

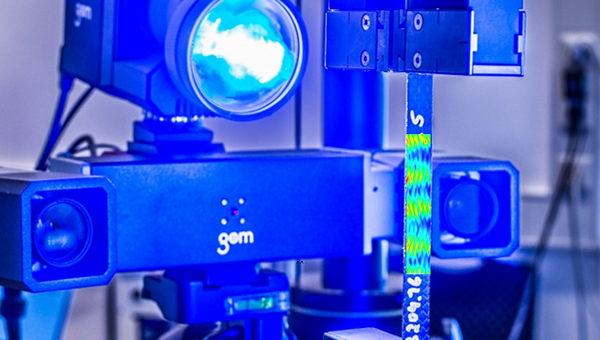

Special structures will be formed in the department and a number of methods for mechanical, applicational, microscopical and physico-chemical characterization method are used and partial developed. Modelling and simulation are used as a substantial research element for a deeper understanding of structure-property relations.