Measurement of powder conductivity

Dr. W. Jenschke, V. Körber, E. Stündel, Dr. J. Pionteck, Dr. B. Krause

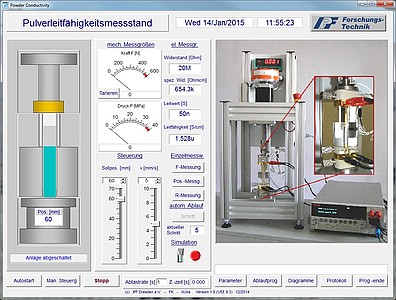

Description

The device was set up in order to measure the electrical conductivity of powdery substances that are the basis of antistatic or electrical conductive modification of thermoplastics. The powder to be examined is filled into a cylinder and compressed by a piston. During the compression process, the electric resistance is continuously measured between two electrodes situated on top of the piston and on the bottom of the cylinder. The conductivity derived from the resistance and the geometry data is then recorded against the pressure. The control of the device as well as the data acquisition and analysis is carried out by a custom-made software developed with TestPointTM. The software allows user programming of different cycles and automatic control.

Technical Data

Motor: Step motor ST5918L from Nanotec, axial force: 1000 N, encoder SMCI44 with RS 422 interface

Encoder for actual value: 8.9081 from Fritz Kubier GmbH with RS 485 interface

Force sensor: Miniatur-Zug-Druckkraftsensor 8417-6001 from Burster, nominal force: 1000 N, digital display unit 918023 with RS 232 interface

Resistance meter: DMM 2001 from Keithley Instruments with GPIB interface

PC control by USB interface

Software: Custom-made Agilent VEE application

Inner diameter of cylinder: 5 mm

Maximum pressure: 30 MPa

Contact:

Dr. B. Krause (Functional Nanocomposite and Blends)

Dr. W. Jenschke (Research Technology division)