Laboratory Electron Modification

Electron accelerators

| parameters | ELV-2 | finger emitter | planar emitter |

|---|---|---|---|

| emitter is coupled to an robot | emitter is coupled to an robot | ||

| electron energy | 0,6 - 1,5 MeV | 80 - 150 keV | 80 - 300 keV |

| electron current | < 4 mA | < 0,1 mA | < 10 mA |

| working width | 8 - 100 cm | 0,8 cm | 25 cm |

| manufacturer | BINP | electron crosslinking AB | COMET AG |

Conveyor system for component parts and pellets

- maximum speed: 12 m/min

- maximum samples size: 1 m x 2 m

High temperature treatment

- maximum sample size: 20 cm x 20 cm

- maximum temperature: 400 °C

- gas atmosphere: vacuum and special gases

Robot controlled edge modification of component parts

- size of parts: 100 cm x 300 cm

- gas atmosphere: air

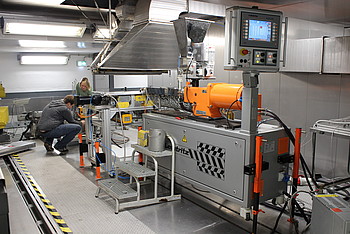

Electron induced reactive processing of polymer compounds

- throughput: 2 ... 5 kg/h

- gas atmosphere: air and nitrogen

Monitoring

- EPR Spectroscopy (Magnettech)