Composites, blockcopolymere and blends containing carbon nanostructures

The aim of the work is to integrate conductive carbon nanostructures into insulating polymer matrices via melt or solution processing and to characterise the composite properties. The main focus is on electrical properties of the composites and blends, but also on influencing mechanical, rheological, thermal, tribological, thermoelectric, sensory and shielding properties as well as fire behaviour. The fillers investigated include single- and multi-walled carbon nanotubes (CNT), carbon nanofibres (CNF), expanded graphite (EG), reduced graphene oxide (rGO) and conductive carbon black (CB), with investigations on CNT forming the focus of the work. The conductivity equipment, which is a prerequisite for thermoelectric, sensory and shielding properties, is achieved by the formation of a percolation network of the conductive fillers in the insulating polymer matrix. In addition to single fillers, filler combinations of several conductive or conductive with non-conductive fillers are also investigated.

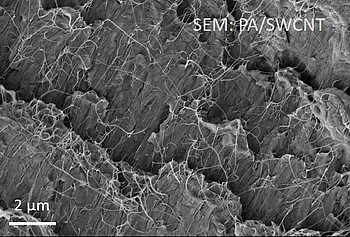

1) Thermoplastic composites via melt processing

The focus is on investigations of the influence of melt processing conditions on the achievable distribution of fillers during composite production (melt mixing in small volume mixers and laboratory extruders) and during moulding (sheet pressing, injection moulding, melt spinning) and their correlation to resulting properties. The underlying processes of deagglomeration, distribution, network formation, aggregation, orientation and alignment of the nanofillers, and in semi-crystalline polymers of crystallisation, strongly influence the properties of the composites, especially in the case of CNTs. In addition, structural features of the fillers such as their morphological nature and surface functionalisation strongly influence the interactions at the phase interfaces, the distributability of the fillers in a matrix, the phase adhesion as well as the stability of the dispersion in processing steps. Therefore, work on modifying the fillers with reactive groups or other substances, e.g. intrinsically conductive polymers, is an essential part of the research.

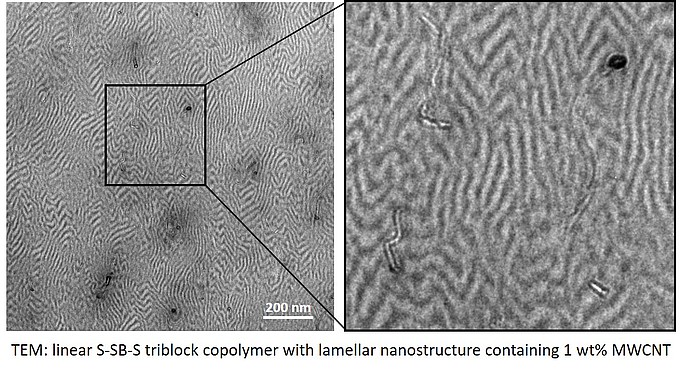

2) Structure-property relationships in nm-structured block copolymer/carbon nanotube composites

The work focuses on developing a fundamental understanding about the mechanisms of dispersion and localisation of CNTs in nanostructured block copolymers (BCPs). The influence on the phase behaviour of BCPs and on the interactions at the interfaces as well as their effects on the morphological, mechanical and electrical behaviour of the BCPs are investigated. The exceptional nanostructured morphology of the block copolymers will be used for a defined localisation of CNTs in one phase or at the interface of both phases via melt mixing and solution mixing. The advantage of such a modification is the significant reduction of the required filler content compared to homopolymer/CNT composites in order to achieve electrical percolation. Thus, on one hand costs are saved and on the other hand it offers the possibility to maintain the very good mechanical properties or to significantly increase the toughness and stiffness in the BCPs. Due to the small dimensions of the BCP nanostructures, it is necessary to choose CNTs with small diameters and lengths and, when selecting the block copolymers, to give preference to materials with lamellar, co-continuous or cylindrical structures with large domain spacing. To optimise the interfacial interactions between nanofiller and BCP phases, CNTs are modified by defined shortening and/or chemical functionalisation. Conductive BCP composites developed in such a way are being investigated for their suitability as sensory materials in the field of deformation or gas sensing.

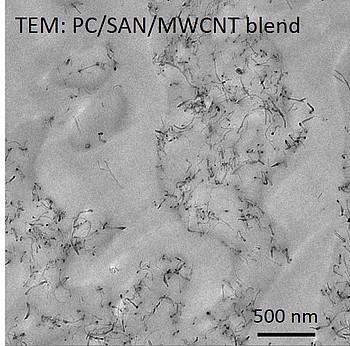

3) Polymer blends with conductive fillers

In polymer blends, the effect of conductive fillers depends mainly on their localisation and the morphology type of the blend. In immiscible polymer blends, fillers accumulate in the thermodynamically preferred component, unless steric or kinetic reasons prevent this. If it is possible to arrange electrically conductive fillers in cocontinuous structures in the phase interface or even in the interface of such a morphology type, very low contents are necessary to achieve electrical percolation. This phenomenon of so-called double percolation has been extensively studied in various blend systems. But even in blends that are miscible in the melt state (example PVDF-PMMA), crystallisation-induced phase separation can cause different localisations of nanofillers, which can significantly influence the composite properties. Such selectively filled blends are particularly interesting for sensory properties (liquid and gas detection) and electromagnetic shielding.

Flyer

- Nanocomposites and blends based on thermoplastics and nanoscale carbon allotropes

- Electrically conductive thermoplastic composites and blends with nanoscale fillers

- Electrically conductive polymer/CNT composites with application potential for sensor technology

Contact person

Coworkers

Dr. Beate Krause

Dr. Ulrike Staudinger

Manuela Heber

Ulrike Jentzsch-Hutschenreuther